Why Choose Customized Hot Dip Galvanized Coils for Your Projects: Unmatched Durability and Versatility

Release time:

2025-06-13 14:40

Why Choose Customized Hot Dip Galvanized Coils for Your Projects

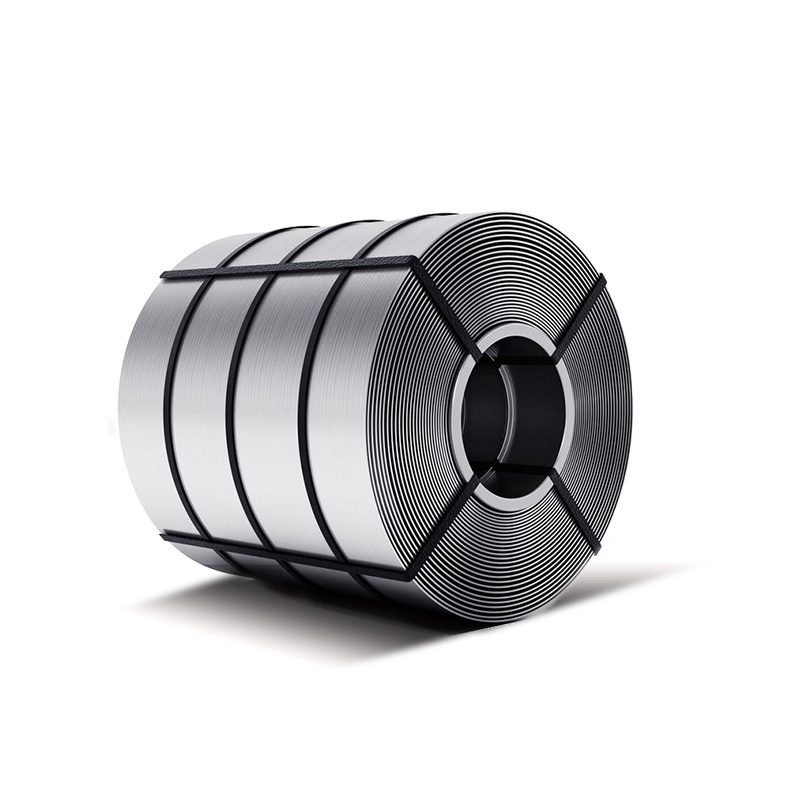

In the ever-evolving landscape of construction and manufacturing, the choice of materials significantly impacts project outcomes. Among the abundance of options available, **hot dip galvanized coils** stand out due to their exceptional properties, versatility, and long-term benefits. This article will delve into the compelling reasons to opt for customized hot dip galvanized coils for your projects, ensuring you make an informed decision that aligns with your specific requirements.

Understanding Hot Dip Galvanization: A Process Overview

Hot dip galvanization is a process that involves the application of a protective zinc coating to steel or iron to prevent rusting. The process entails submerging the metal in a molten zinc bath, resulting in a robust bond between the zinc and the substrate. This creates a **corrosion-resistant layer** that significantly extends the lifespan of the metal.

The Advantages of Hot Dip Galvanized Coils

**Hot dip galvanized coils** offer numerous advantages that make them an ideal choice for a variety of applications:

1. Exceptional Corrosion Resistance

One of the primary benefits of hot dip galvanized coils is their **superior resistance to corrosion**. The zinc coating forms a protective barrier that prevents moisture and environmental elements from reaching the underlying metal. This feature is particularly crucial in industries where exposure to harsh conditions is common, ensuring longevity and reducing maintenance costs.

2. Customization for Specific Needs

Customized hot dip galvanized coils allow for adjustments in size, thickness, and coating weight to meet specific project requirements. Whether you need coils for roofing, siding, or structural applications, the flexibility in customization ensures that you receive a product tailored to your needs.

3. Cost-Effectiveness and Longevity

Although the initial investment in hot dip galvanized coils may be higher than other materials, their **long-term cost-effectiveness** is undeniable. The extended lifespan reduces the need for frequent replacements, leading to lower overall expenses in the long run.

4. Sustainability and Environmental Considerations

Hot dip galvanization is also an environmentally friendly option. The process uses recyclable materials, and the durability of galvanized products minimizes waste. Choosing hot dip galvanized coils contributes to **sustainable construction practices**, aligning with modern environmental standards.

Applications of Customized Hot Dip Galvanized Coils

The versatility of hot dip galvanized coils makes them suitable for a wide range of applications across various industries. Here are some notable examples:

1. Construction and Infrastructure

In the construction sector, hot dip galvanized coils are extensively used for roofing, gutters, and siding. Their corrosion resistance is particularly advantageous in high-moisture environments, ensuring the integrity of structures over time.

2. Automotive Industry

The automotive industry benefits from hot dip galvanized coils for manufacturing components that require strength and durability. The corrosion resistance ensures that auto parts maintain their functionality and appearance throughout their lifespan.

3. Agricultural Applications

Hot dip galvanized coils are widely used in agricultural equipment and structures, such as silos and fencing. The ability to withstand harsh outdoor conditions makes them an invaluable resource in this sector.

4. Electrical and Telecommunications

In the electrical and telecommunications industries, hot dip galvanized coils are utilized for poles, towers, and cable trays. The protective coating ensures that these components remain functional and reliable in various environmental conditions.

Factors to Consider When Choosing Customized Hot Dip Galvanized Coils

When selecting customized hot dip galvanized coils for your projects, several factors warrant consideration:

1. Gauge and Thickness

The gauge and thickness of the coils can significantly impact their performance. Understanding the specific requirements of your project will guide you in choosing the appropriate measurements.

2. Coating Weight

The coating weight, measured in grams per square meter, determines the level of corrosion resistance. A higher coating weight typically provides better protection, making it essential to select a weight that aligns with environmental conditions.

3. Surface Finish

The surface finish of the galvanized coils can also affect their usability. Options range from a smooth finish to various textures, depending on the application and aesthetic preferences.

How to Source Quality Customized Hot Dip Galvanized Coils

Finding a reliable supplier is crucial to obtaining high-quality customized hot dip galvanized coils. Here are steps to help you source the best options:

1. Research Reputable Suppliers

Conduct thorough research to identify suppliers who specialize in hot dip galvanized products. Look for companies with a proven track record of quality and customer satisfaction.

2. Evaluate Certifications and Standards

Ensure that the supplier adheres to relevant industry standards and certifications. This guarantees that the products meet specific quality and safety requirements.

3. Request Samples

Before making a bulk purchase, request samples of the galvanized coils to assess their quality and suitability for your projects. This step is crucial in making an informed decision.

4. Compare Pricing and Terms

While quality is paramount, it's also essential to compare pricing and terms of service among different suppliers. This will help you find a balance between cost and quality.

Common Misconceptions About Hot Dip Galvanized Coils

Despite the numerous advantages of hot dip galvanized coils, several misconceptions persist. Here, we address some of these misunderstandings:

1. Hot Dip Galvanized Coils Are Only for Outdoor Use

While hot dip galvanized coils excel in outdoor environments, they are also suitable for indoor applications where moisture or humidity may be a concern.

2. The Coating Is Prone to Peeling

The zinc coating on hot dip galvanized coils is highly durable and adheres strongly to the substrate, making it resistant to peeling under normal conditions.

3. They Are Only Suitable for Certain Industries

Hot dip galvanized coils are versatile and applicable across various industries, from construction to agriculture and automotive.

Frequently Asked Questions (FAQs)

1. What is the lifespan of hot dip galvanized coils?

The lifespan of hot dip galvanized coils can vary based on environmental conditions, but they typically last 20 to 50 years, or even longer in less corrosive environments.

2. Can hot dip galvanized coils be painted?

Yes, hot dip galvanized coils can be painted. However, proper surface preparation is essential to ensure paint adhesion.

3. Are hot dip galvanized coils environmentally friendly?

Absolutely! The hot dip galvanization process utilizes recyclable materials, making it an environmentally friendly choice.

4. What thickness of hot dip galvanized coils do I need for my project?

The required thickness depends on the specific application and environmental conditions. Consulting with a supplier can help you determine the best option.

5. How do I maintain hot dip galvanized coils?

Maintenance is minimal. Regular inspections for damage or corrosion are recommended, but no special treatments are generally required.

Conclusion

Choosing customized hot dip galvanized coils for your projects offers a multitude of benefits, including outstanding corrosion resistance, cost-effectiveness, and versatility across various applications. Their ability to withstand harsh environmental conditions and provide long-lasting performance makes them an ideal choice for industries ranging from construction to agriculture. By understanding the intricacies of hot dip galvanization and considering your specific project requirements, you can make informed decisions that enhance the efficiency and sustainability of your operations. Investing in high-quality, customized hot dip galvanized coils not only protects your project but also contributes to a more sustainable future.

Previous article

Previous article